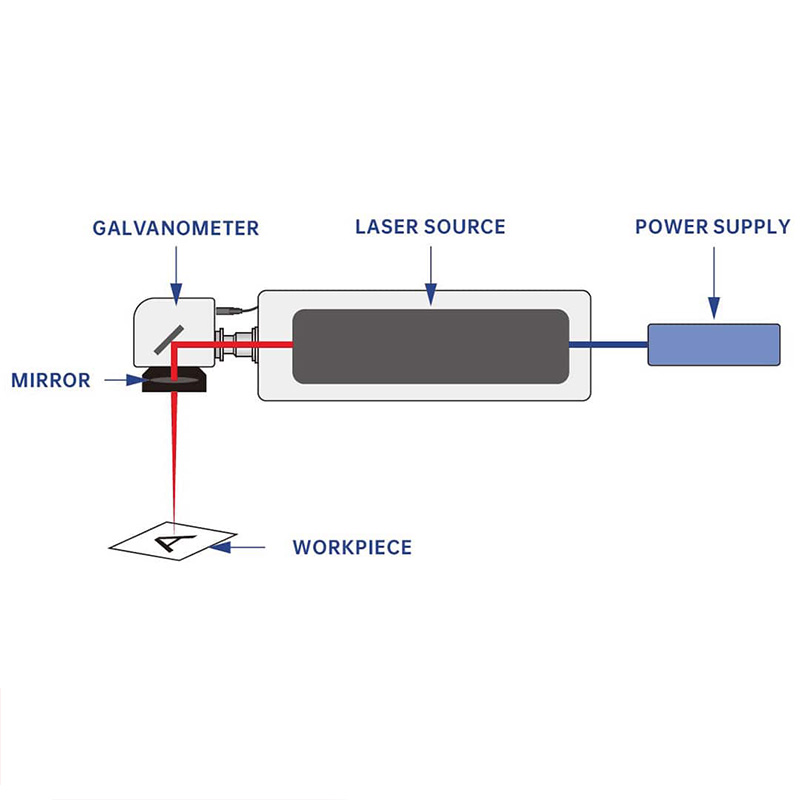

CO2 Laser Engraving and Cutting Machine, In today’s world, laser technology has become one of the most effective methods of manufacturing and processing materials. Among the different types of lasers, CO2 laser is the most popular option for engraving and cutting due to its high accuracy, reasonable power and ability to work with a variety of materials. This type of laser uses carbon dioxide (CO2) gas and an electrical energy source to create a focused, high-power beam that has the ability to cut and engrave on various surfaces with unparalleled precision.

CO2 laser engraving and cutting machine

The main feature of CO2 lasers is their flexibility in working with a variety of materials. These devices are capable of engraving and cutting on wood, plexiglass, glass, leather, fabric, plastic, cardboard, ceramics, and even some coated metals. This variety of applications has led to the use of CO2 laser devices in various industries such as advertising, interior decoration, packaging, fashion and clothing, crafts, architecture, and even visual arts.

One of the most attractive features of this technology is its extremely detailed engraving. CO2 machines can create extremely precise designs with thin and delicate lines on the material without damaging the original texture. This feature has led many designers and artists to use this technology to create their own unique works; from decorative paintings to personalized gift boxes.

In the cutting sector, the CO2 laser also appears very powerful. The laser beam, with its high focus and high heat, can easily cut materials of different thicknesses without the need for physical contact. This feature not only increases the accuracy of the work, but also prevents tool wear and tear. In addition, the edges cut by the laser are usually smooth, clean and do not require additional polishing, which is a great advantage in the production process.

Ease of use and customizable software are other advantages of CO2 cutting and engraving machines. These machines usually come with software that supports various graphic formats, including DXF, AI, BMP, JPG, and PLT. This allows users to design their own designs using software such as CorelDRAW or AutoCAD and easily send them to the machine.

In terms of safety, CO2 laser devices provide safe conditions for users by having protective systems such as locking doors, smoke sensors, ventilation systems, and automatic shut-off. Also, the power consumption of these devices is economical and cost-effective in relation to the output power.

The CO2 laser marking machine is a 20,000 hour long-life device whose output laser beam has a wavelength of 10600 nm and is highly dependent on heat due to this long wavelength (CO2 laser markers have a wavelength that is 10 times longer than conventional fiber systems). They are suitable for material removal and marking on organic materials such as cardboard, plastic, glass, ceramics and wood, non-metals, and marking on labels made of special materials or light-sensitive dyes.

CO2 laser engraving and cutting machine

The advantages of this laser include the fact that the CO2 laser can mark surfaces using small dots, which facilitates a more uniform appearance of materials by minimizing the risk of radial cuts and cracks, and that the CO2 laser engraving machine is capable of engraving and cutting a wide range of materials. This machine is used in the signmaking, packaging and many other industries. This machine can be used to mark serial numbers, barcodes, logos, etc.

Common applications of CO2 laser

- Engraving and cutting plexiglass signs for advertising

- Construction of exhibition stands

- Cutting wooden or MDF pieces for decoration

- Producing special and creative packaging

- Engraving on glass, leather and fabric for luxury products

- Making precise model parts for architects and industrial designers

Reviews

There are no reviews yet.